Product Description

SUPERSEAL Dimpled Membrane is an extremely durable black dimpled sheet made from High Density Polyethylene (HDPE) plastic. It is mechanically fastened to a foundation wall at final grade height.

- It can be installed on any type of foundation on the exterior or interior including poured concrete walls, block walls, brick or stone walls, insulated concrete form walls, and more.

- The dimples in the membrane are 5/16” in height, which create a drainage space or airgap between the wall and the back of the membrane. This prevents any soil and/or backfill material from touching the wall itself. The backfill rests on the outside of the membrane and water can not penetrate through the plastic.

- Surface water migrates down through the backfill to the drainstone and into the drain pipe at the bottom, near the footing. In the event any water does enter the drainage space, it will fall by gravity to the bottom and migrate into the drainage system at the footing.

- It is easy to install with or without additional coatings, in any weather condition, and can be backfilled immediately.

- When installed with the appropriate accessories it is backed with a 40 year warranty.

Protect your home with SUPERSEAL in 3 easy steps:

Protect your home with SUPERSEAL in 3 easy steps:

Unroll the membrane, fasten to the wall, and back fill.

PERMANENT BARRIER BRIDGES WALL CRACKS

SUPERSEAL Dimpled Membrane is made from tough, long lasting plastic that keeps exterior moisture out. It prevents backfill material from touching the foundation wall and bridges typical wall cracks with ease and can be backfilled right away.

DRAINAGE SPACE

The dimples in the membrane create a drainage space that allows the wall to breathe. It keeps 100% of the head water pressure off the face of the wall. This space allows moisture to condensate outward on to the membrane. By gravity, the moisture then falls to the footing drain for removal.

Rolls from 3’6, 5′, 6′, 6’7″,7’4″,7’11”, 8’11” rolls, and the accessories are available to our U.S.A. customers.

Rolls from 3’6, 5′, 6′, 6’7″,7’4″,7’11”, 8’11” rolls, and the accessories are available to our U.S.A. customers.

Ship any size order for just $99.99.

For questions or inquiries about contractor pricing, contact us.

PRICING

- Clearance sale on our 7’11” brown rolls

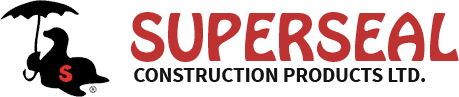

- Use Membrane Cap Molding and Super Plugs to fasten it to the wall.

SHIPPING

$99.99 per order flat rate Shipping: 3 – 7 Business Days

All shipping times are estimated and may not be 100% accurate. Shipping times may vary based on location and order size. Most orders are shipped within the next business day.

INSTALLATION:

Materials and tools will vary depending on your application and the type of foundation. For more detailed instructions click on your application page above.

SUPERSEAL DETAILED INSTRUCTIONS: Installation Instructions

The keys to a good installation

- Install to final grade height.

- Incorporate into the drain system at the footing.

- It is better if the membrane is installed prior to installing perforated pipe and the drainstone.

- Ensure you have enough membrane, plugs, and molding strips to complete the area that you are protecting.

- Follow the Installation instructions.

A waterproof coating is not required but provides additional protection.

PREPARATION

- Ensure the site is safe and accessible.

- Make sure that you have all the tools and material necessary to complete the job.

- Determine the roll heights required and measure the length needed.

- Determine the final grade height and snap chalk lines. The product should not be exposed to UV for long periods of time.

- Clean the footing off and repair any imperfections.

- Use a SUPERSEAL Brush or Trowel Grade Mastic (or equivalent) to patch tie holes, honeycombing, protrusions, etc.

1. HANGING THE MEMBRANE

- Hold the membrane at the chalk line with the dimples go towards the wall.

- Keeping the membrane tight to the wall and install a SuperPlug about 8-12 inches down from the top and every 8-10 feet in length. Continue this process until all the membrane is hanging on the wall.

TIP, The membrane can sit directly on top of the footing or extend out to the edge of the footing.

OVERLAPS AND SEAMS:

- Overlap a minimum 6″ for any horizontal or vertical seam.

- For horizontal seams, the top piece must be on top of the bottom piece. This prevents the possibility of water migrating through the seam.

- Use SUPERSEAL Mastic (or equivalent) between the 2 pieces (Optional but recommended).

- Fasten the seam with a Super Plug every 2 feet.

CORNERS:

- When you come to an inside or outside corner, keep the membrane tight to the wall.

- Fasten a plug 4-6 inches from the corner, every 2 feet vertically.

- If you are overlapping onto the footing, cut the membrane from the fold in the footing to the edge ofthe membrane. Fold around or through the corner.

WINDOW WELLS:

Windows are the # 1 cause of water penetration. Concrete cracks at the weakest point and that is usually at the bottom of a window opening. For windows that are lower than grade height and require a window well,

- Fasten the membrane as close the all edges of the window as possible.

- Cut the membrane just inside the window well opening on each side (2″).

- (HINT: you can install molding for the window now or when you do the rest of the molding or cap)

After you have hung all the membrane, go back to where you started and begin fastening the membrane to the wall.

2. PLUGGING THE MEMBRANE

In a “W” pattern, fasten the membrane to the wall with Super Plugs.

- 8 inches down from the top, install a row of Super Plugs every 16 inches horizontally.

- Install a 2nd row of Super Plugs 8 inches down from row 1 and offset it so it forms a “W pattern”

- In the middle and the bottom, fasten a plug every 6-10 feet horizontally so the membrane stays tight against the wall. At the bottom, fasten the plugs as close to the footing as possible.

- Plugs are installed every 2 feet vertically on all overlaps

- Plugs are installed every 2 feet vertically and 4-6 inches in from corners. (inside and outside corners)

3. INSTALLING THE MOLDING

SUPERSEAL DimpleGrip or Membrane Cap Molding must be installed on all open edges.

DimpleGrip Molding Is a heavy duty molding system. Each piece is 3.5″ wide, 4′ long and comes in bundles of 10 (40′).

It has 3 rows of dimples that interlock with the Dimpled Membrane and a soft lip that seals the the top of the wall. DimpleGrip Molding can be installed horizontally or vertically. If the membrane is cut on an angle, the molding will not fit. In this case the Membrane Cap Molding is required.

Membrane Cap Molding caps the top and sides of the membrane. Each piece is 1.5″ wide, 4′ long and comes in bundles of 10 (40′). It is “L” shaped and can be installed horizontally, vertically, and on any angle. You can use the Membrane Cap throughout your entire job, but you will use more Super Plugs than using DimpleGrip Molding. (see detailed instructions)

The DimpleGrip and the Membrane Cap are fastened every 6-8 inches. Butt each piece together as you go.

Once the molding has been installed, it is good practice to walk around and patch any open spots.

Ensure that you have a minimum of 6 inches of drainstone around the drainpipe, on the footing and up the membrane at the bottom.

FASTENING SYSTEMS

There are two molding systems to choose from. The DimpleGrip System and the Standard System

1) The DimpleGrip System requires DimpleGrip Molding and SuperPlugs. (see below)

2) The Standard System requires Membrane Cap and SuperPlugs. (see below)

DIMPLEGRIP FASTENING SYSTEM

(Premium system for ICF’s & Concrete Block)

Requires DimpleGrip Molding for horizontal and vertical edges. Super Plugs fastened 12-16″ OC and Membrane Cap for sloping areas. Small Plugs can be used to fasten corners and overlaps.

1 roll of membrane requires approximately:

- 2 bundles of DimpleGrip

- Membrane Cap for slopes and angles – 40 feet per bundle

- SuperPlugs: 2 bags for 3’6″ to 7’11” per roll or 3 bags for 8’11” to 9’11” per roll

STANDARD FASTENING SYSTEM

(Most economical material cost system)

Requires Membrane Cap for all edges and SuperPlug fastened 8″ OC. Small Plugs can be used to fasten corners and overlaps.

1 roll of membrane requires approximately:

- 2 bundles of Membrane Caps

- SuperPlugs: 3 bags for 3’6″ to 7’11” per roll or 4 bags for 8’11” to 9’11” per roll

SuperPlugs

Each plug has 5 dimples that interlock into the membrane providing superior holding strength over a single plug. Recommended for all areas.

Membrane Cap

Smooth L shaped molding that caps the membrane – 40 feet per bundle.

DimpleGrip Molding (Optional)

Interlocks with the top 4 rows of the membrane along its entire length. Provides superior strength and uses less Super Plugs and labor.

Small Plugs (Optional)

Fits into individual dimple. Used mostly for contractors with a nail gun system.

TOOL REQUIRED

CONCRETE NAIL GUN – For poured walls

The following guns work very well with the system as they hold 40 nails and the installation is quick. The nose piece friction fits the SuperPlug and Small Plug perfectly without any fancy adapters.

HILTI GX 120 https://www.hilti.ca/direct-fastening/electrical-%26-mechanical-fastenings/r3697

HILTI G3 https://www.hilti.ca/direct-fastening/drywall-applications/3538128

Ramset Trakfast http://www.ramset.ca/product/47/trakfast-gas-powered-tool

TAPCON – Poured and Block wall Foundations

You can also use 1 ¼ inches Tapcon screws ( 1 ¼ inches x 3/16 inches hexagon head is best). This is a predrill system. This is more time consuming than a nail gun but works well if it you are doing a small job or it’s a onetime use. TAPCON https://www.tapcon.com/products/concrete-screw-anchors

CONCRETE NAILS – Hand nailing

It is possible to use standard concrete nails and a hammer. Concrete varies in hardness in different regions. This method is labour intensive and time consuming. This is usually only done when the concrete is freshly poured and is in the curing process. Test a spot first before continuing.

DECK SCREWS

Standard deck screws are used on ICF and Wood foundations only.

Other tools you may need:

Eye protection, Ear protection, gloves, hammer, Tool belt, tape measure, marker, chalk line, utility knife, ladder, caulking gun or putty knife.

Specifications

| PART # | IMPERIAL | METRIC | ||||

| SM36107 | 3’6″ X 65’6″ | 230ft² | 29 lbs | 1.07m x 20m | 21.4m² | 13kg |

| SM50150 | 5’0″ X 65’6″ | 325ft² | 40 lbs | 1.5m x 20m | 30m² | 18kg |

| SM60183 | 6’0″ X 65’6″ | 393ft² | 49 lbs | 1.83m x 20m | 36.6m² | 22kg |

| SM67200 | 6’7″ X 65’6″ | 431ft² | 53 lbs | 2.0m x 20m | 40m² | 24kg |

| SM74224 | 7’4″ X 65’6″ | 480ft² | 59 lbs | 2.24m x 20m | 44.8m² | 27kg |

| SM80240 | 7’11” X 65’6″ | 518ft² | 64 lbs | 2.4m x 20m | 48m² | 29kg |

| SM81127 | 8’11” X 65’6″ | 583ft² | 72 lbs | 2.7m x 20m | 54m² | 33kg |

| SM91130 | 9’11” X 65’6″ | 648ft² | 80 lbs | 3.0m x 20m | 60m² | 36kg |

| 11’6 & 13’2 ROLLS ARE ONLY AVAILABLE AS A SPECIAL ORDER ITEM | ||||||

| SM11635 | 11’6″ X 65’6″ | 754ft² | 93 lbs | 3.5m x 20m | 70m² | 43kg |

| SM13204 | 13’2″ X 65’6″ | 861ft² | 107 lbs | 4.0m x 20m | 80m² | 47kg |

Tested and Passes The FollowingICC ESR-3107, CCMC# 13098-R, CCMC# 13099-R, CGSB, NBC 9.13.3, 9.14.2.1 & IRC R405, R406 |

|

|

Dimpled Sheet

|

High Density Polyethylene (HDPE)

|

|

Available Colors

|

Black (Standard), Brown (Special order)

|

|

Compressive Strength

|

5200 psf (250 kN/m² )

|

|

Dimple Height

|

5/16″ (8mm)

|

|

Fire Rating

|

B2 (DIN 4102)

|

Installation

WHAT IS SUPERSEAL DIMPLED MEMBRANE?

SUPERSEAL Dimpled Membrane is an environmentally friendly 24 mL high-density polyethylene membrane. SUPERSEAL Dimpled Membrane is resistant to a wide range of chemicals, impervious to root penetration, rot-proof, and unaffected by soil bacteria, fungi, and alkaline environments.

What is it used for?

SUPERSEAL Dimpled Membrane is a permanent waterproofing and drainage membrane that can be installed on any type of foundation, used as a subfloor, under floor slabs, and retrofit applications.

What areas of my home can I use it on?

You can use the membrane as a subfloor, leaky interior basement walls, in crawl spaces, and cellars to help control musty odours.